Professional cutting technology

Modern and sustainable cutting techniques, precision in optima forma!Panhuizerweg 11

4041 CN, Kesteren

0488 483 595

About us

In 2019, Snijbedrijf Koetsier, a company with 30 years of cutting experience, has been renamed to Heudra Snijtechniek. In addition to tailor-made products, we provide welding constructions and, in cooperation with sister company Heudra Metaalbewerking, we can also unburden you in the field of CNC turning and milling work.

Welcome

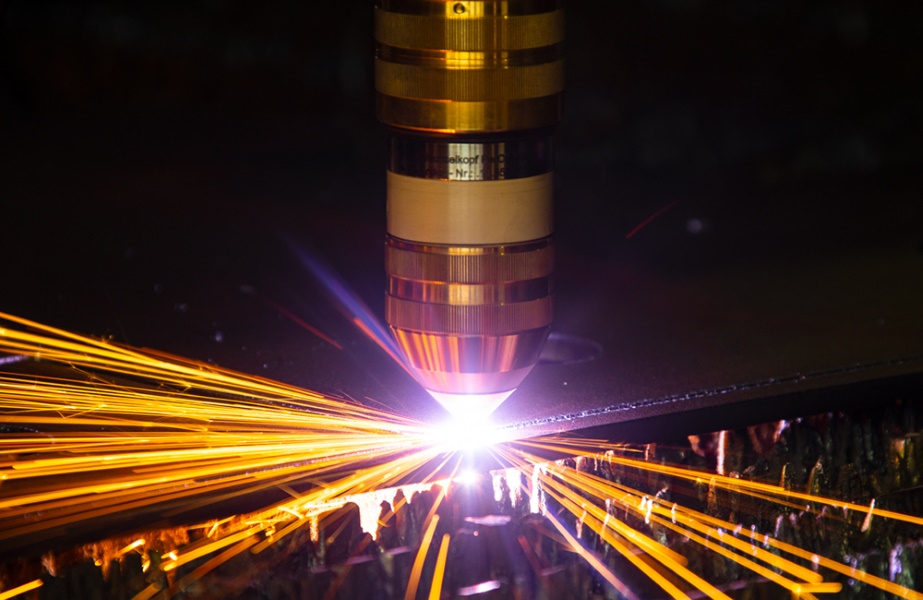

Cutting is precision work. Heudra Snijtechniek utilizes advanced oxyfuel and plasma techniques to cut all types of steel to the desired dimensions. The usual sizes are up to 300 millimeters thick, 3 meters wide and 12 meters long. The length can be increased as required. This way we have a tailor-made solution for everyone’s wishes.

Contact

Do you have any specific wishes or would you like to discuss certain possibilities with us? We look forward to assess your assignment, from advice to drawing and from guidance to execution.

OXYFUEL CUTTING

Oxyfuel cutting, also known as fire cutting, is a thermal process that is mostly applied to steel plates with thickness ranging from 15 to 300 millimeters.

Our vision

Heudra Snijtechniek is all about quality, efficiency and commitment. We are a medium-sized company, which is why we are close to the customer. We like to think along and we can be flexible – regardless of the order size. For us, it is a challenge to see if we can “cut residues” with as little waste as possible. For you, that will lower the price – and we are committed to sustainability.

PLASMA CUTTING

Plasma cutting is an electrical process that creates an electric arc between a tungsten electrode. The gas is partially ionized by the electrical charge, after which it turns into plasma.